Predictive Maintenance

Quick Navigation:

- Predictive Maintenance Definition

- Predictive Maintenance Explained Easy

- Predictive Maintenance Origin

- Predictive Maintenance Etymology

- Predictive Maintenance Usage Trends

- Predictive Maintenance Usage

- Predictive Maintenance Examples in Context

- Predictive Maintenance FAQ

- Predictive Maintenance Related Words

Predictive Maintenance Definition

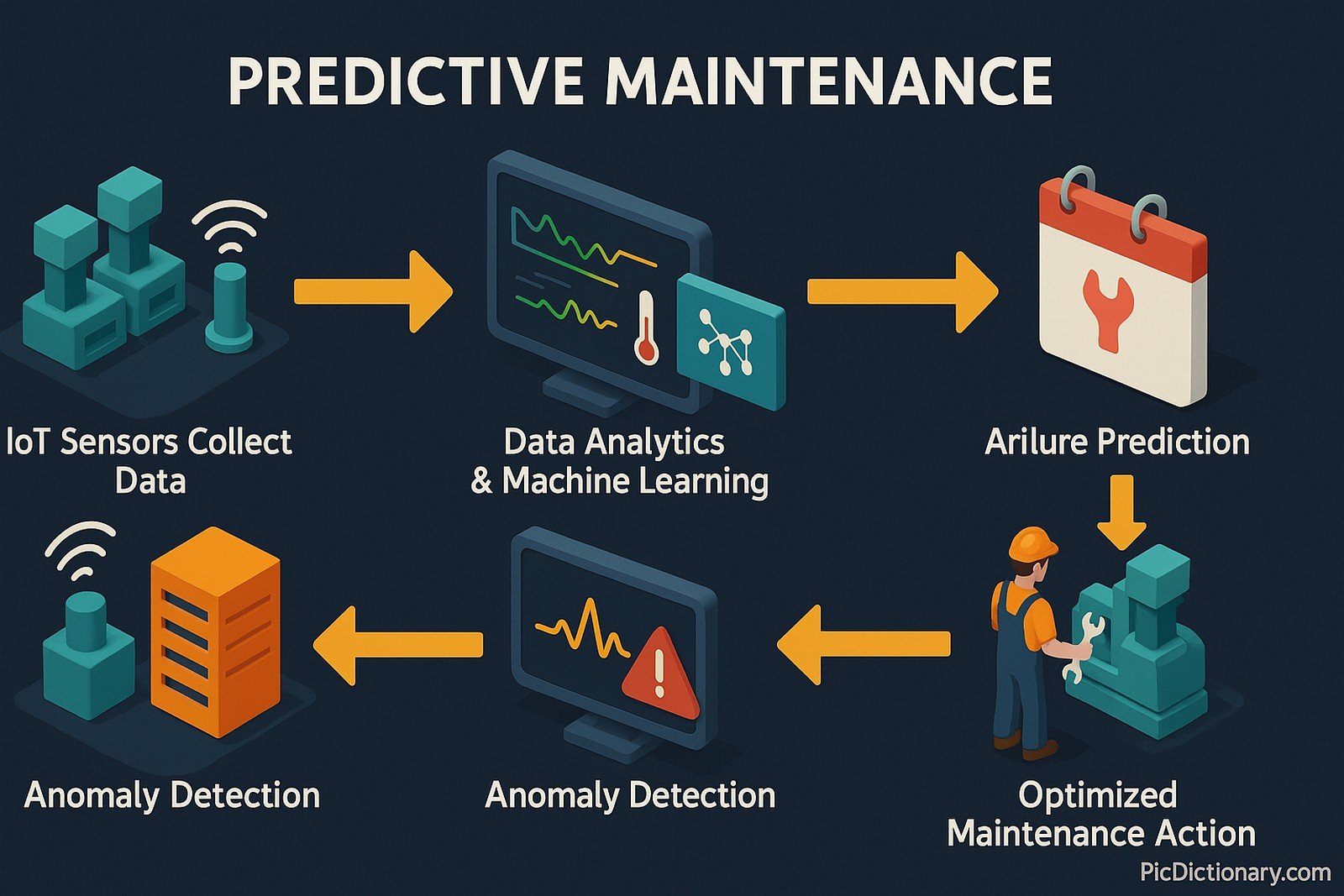

Predictive maintenance is a proactive maintenance strategy that uses data analytics, machine learning, and IoT sensors to monitor equipment conditions and predict failures before they occur. By analyzing real-time and historical data, predictive maintenance helps organizations reduce downtime, extend asset life, and optimize maintenance schedules. Key technologies used in predictive maintenance include AI-driven anomaly detection, vibration analysis, thermal imaging, and predictive modeling techniques.

Predictive Maintenance Explained Easy

Imagine you have a bike, and you don’t want it to break while you’re riding. Instead of waiting for a problem, you use a special tool that tells you when your tires are getting low on air or when your brakes might stop working soon. This way, you fix things before they break. That’s what predictive maintenance does for machines—it helps fix them before they stop working!

Predictive Maintenance Origin

The concept of predictive maintenance evolved from traditional preventive maintenance practices in industrial settings. With the rise of IoT and AI-driven analytics in the late 20th and early 21st centuries, industries began using real-time sensor data to improve failure predictions and optimize maintenance strategies.

Predictive Maintenance Etymology

The term "predictive maintenance" originates from the word "predictive," meaning forecasting or anticipating, and "maintenance," referring to the upkeep of machinery and equipment.

Predictive Maintenance Usage Trends

Predictive maintenance has seen rapid adoption across industries such as manufacturing, aviation, energy, and healthcare. As businesses strive to minimize unexpected failures and reduce maintenance costs, the integration of AI, big data, and IoT sensors has driven the growth of predictive maintenance solutions. The market for predictive maintenance continues to expand with the increasing reliance on automation and smart technologies.

Predictive Maintenance Usage

- Formal/Technical Tagging:

- Condition Monitoring

- Industrial IoT

- Predictive Analytics

- Machine Learning in Maintenance - Typical Collocations:

- "predictive maintenance model"

- "IoT-based predictive maintenance"

- "real-time predictive maintenance"

- "machine learning for predictive maintenance"

Predictive Maintenance Examples in Context

- Airlines use predictive maintenance to detect engine issues before they cause flight delays.

- Manufacturing plants use IoT sensors to track machinery health and schedule repairs before breakdowns occur.

- Smart buildings monitor HVAC systems to predict and prevent costly failures.

Predictive Maintenance FAQ

- What is predictive maintenance?

Predictive maintenance is a technique that uses data and analytics to anticipate when equipment will need maintenance, preventing unexpected failures. - How does predictive maintenance work?

It collects real-time data from sensors, applies machine learning models, and identifies patterns to predict potential failures. - What industries benefit from predictive maintenance?

Industries such as manufacturing, aerospace, energy, healthcare, and transportation rely on predictive maintenance to improve efficiency. - What are the key technologies in predictive maintenance?

IoT sensors, AI algorithms, vibration analysis, thermal imaging, and predictive modeling are commonly used technologies. - How does predictive maintenance reduce costs?

By preventing unexpected breakdowns, predictive maintenance minimizes repair costs, extends asset life, and reduces downtime. - What is the difference between preventive and predictive maintenance?

Preventive maintenance follows a scheduled routine, while predictive maintenance relies on real-time data to anticipate failures. - Can predictive maintenance be applied to small businesses?

Yes, many cloud-based predictive maintenance solutions are scalable and affordable for small businesses. - What challenges does predictive maintenance face?

Challenges include high initial investment, data integration complexities, and the need for skilled personnel. - How does AI improve predictive maintenance?

AI enhances accuracy in failure predictions by identifying complex patterns in large datasets. - Is predictive maintenance the future of industrial maintenance?

Yes, as technology advances, predictive maintenance will continue to revolutionize how industries manage equipment health.

Predictive Maintenance Related Words

- Categories/Topics:

- Industrial IoT

- Machine Learning in Maintenance

- Asset Health Monitoring

Did you know?

In the aviation industry, predictive maintenance has saved millions of dollars by preventing unexpected engine failures. Airlines use real-time data from aircraft sensors to detect potential issues, reducing maintenance-related flight delays and improving passenger safety.

PicDictionary.com is an online dictionary in pictures. If you have questions or suggestions, please reach out to us on WhatsApp or Twitter.Authors | Arjun Vishnu | @ArjunAndVishnu

I am Vishnu. I like AI, Linux, Single Board Computers, and Cloud Computing. I create the web & video content, and I also write for popular websites.

My younger brother, Arjun handles image & video editing. Together, we run a YouTube Channel that's focused on reviewing gadgets and explaining technology.

Comments powered by CComment